Tube end is pointed to allow gripping by draw bench.

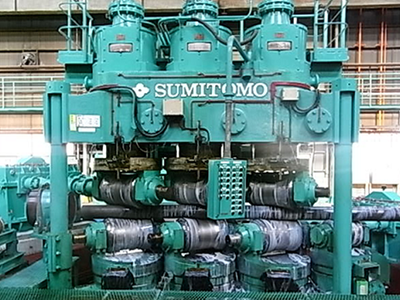

(Swaging Machine, hydraulic forming

machine.)

Heat treatment is given to develop uniformity in material structure.

(Roller hearth type

continuous annealing furnace)

Pickling: To remove surface scale using diluted sulfuric acid

Water washing: To wash away acids with water

Preparation: To form a zinc phosphate coating

Water washing: To remove sludge

Lubrication: To apply Bondalube or Strol Oil according to type of use

Facility for temporary storing of in-process workpieces in order to make up the processing capability

gap between previous and subsequent processes

To ensure that products do not suffer surface scratching, no stacking is permitted in the warehouse.

Tubes are finished to the desired dimensions by drawing through ultra hard drawing die and

plug.

By this cold working, precise tube dimension obtained and mechanical strength is increased.

Final heat treatment is performed to satisfy applicable standard.

Any bends after cold drawing and annealing processes are corrected to form fully straight tubes.

(Roll straightener ,Press straightener)

Ultrasonic inspection or eddycurrent inspection is applied as required.

Both ends of the tube are cut to the required length and chamfered. (High-speed cutter, automatic machine saw)

Dimensional and visual inspection, tensile test, hardness test, micro photogragh, surface roughness measurement.

Any desired form of packaging will be undertaken on request including stenciling.

Maximum care will be taken to ensure safety and prevent the steel tubes from getting wet and corroding in transit.

Depending on demand, cut tubes and other products are supplied out of 11 product warehouses located nationwide.